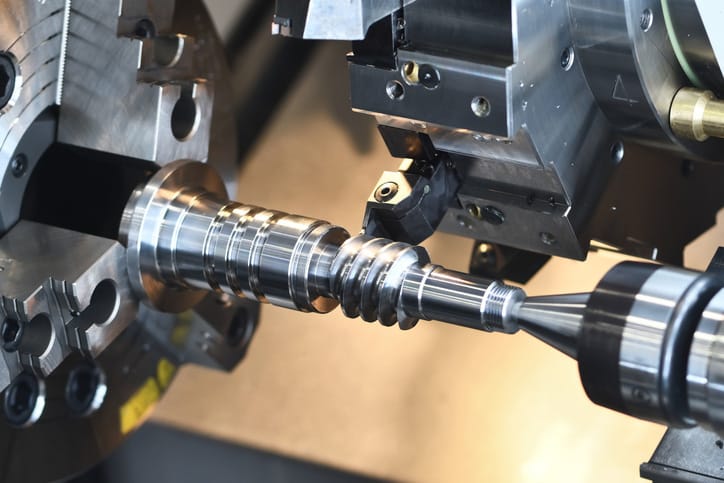

Welcome To Prathamesh Technical Services

Highly Competitive Export Quality

About Us

High Quality Precision Engineering Products

Prathmesh Technical Services Known for supplying of high quality Precision Engineering Products manufacturing company, conducting business in the domain of machine fasteners manufacturing since 2005. The company, founded by Mr. Sitaram Redkar, has since inception, grown to become an exporter to a majority of European clients, catering to all their special needs and international standards. We have expanded our roots not only in the export market, but are also proud to be serving our domestic clients with our world-class products all over India.

Quality Control Process at Prathmesh Technical Services

At Prathmesh Technical Services, we adhere to stringent quality control processes to ensure that every product meets the highest standards of precision and reliability. Our comprehensive quality assurance procedures span every stage of production, from raw material inspection to final product packaging. Here's an overview of our quality control process:

Why Choose US ?

Choose Prathmesh Technical Services for your precision manufacturing needs and experience unparalleled quality, reliability, and customer-centric service

Industry Experience

Over 15 years of specialized experience in precision manufacturing, ensuring expertise and reliability.

Customization:

Tailored solutions designed to meet specific client requirements, enhancing operational efficiency.

Quality Excellence:

Stringent quality assurance measures to ensure products meet high standards of performance and reliability.

Global and Domestic Presence:

Trusted by European clients for adhering to international standards, while serving diverse industries across India.

Innovation Focus:

Continuous investment in advanced technology and R&D to deliver cutting-edge engineering solutions.

Comprehensive Product Range:

Offering a diverse array of precision-engineered products essential for various industrial applications.

Customer Satisfaction:

Commitment to exceeding client expectations through responsive service and support.

Proven Track Record:

Demonstrated success in delivering superior quality and meeting project timelines.

Adherence to Standards:

Ensuring compliance with industry regulations and best practices.

Partnership Approach:

Building long-term relationships based on trust, integrity, and mutual success.

We are Certified Exporter

✖